Automatic system - Endpoints Overview (plus buttons and lights explained)

Overview

The GreaseBoss Endpoint is designed to verify that the correct amount and rate of grease is being delivered to a lubrication point.

To eliminate the risk of undetected faults in hoses or fittings downstream of the supply device, the endpoint should be installed as close as possible to the actual lubrication point – hence the name “endpoint.”

See also: Technical & Product Specifications

Endpoint Highlights

- Installed permanently between the supply method

(e.g. single-point or multi-point auto-lubricator) and the grease point. - Measures and records grease flow delivered to the point.

- Wirelessly communicates to a GreaseBoss Gateway, which sends data to the GreaseBoss Cloud for analysis.

- Factory-configured to communicate via low energy Bluetooth to the gateway.

- Long-life, field-replaceable battery.

- Rugged construction provides environmental and chemical resistance and long service life.

- Low cost per unit, with potential to prevent catastrophic unplanned failures.

- Verifies operation of auto-lubricators, which are often prone to silent failure.

- Provides game-changing insights on lubrication performance and evidence of correct lubrication for warranty claims.

System Integration

- Typically, one endpoint is installed per lubrication point that you want to monitor.

- Multiple endpoints can connect to a single gateway.

- Endpoint data is securely stored in the GreaseBoss Cloud, where you can access it at any time.

- The GreaseBoss Cloud can be configured to generate reports that combine:

- Endpoint activity (automatic lubrication), and

- Manual greasing activity from other GreaseBoss devices (e.g. the GreaseBoss Head Unit).

Diagrams for multi-point systems:

Endpoints in a multi-point system per point

Endpoints in a multi-point system per point

Endpoints in a multi-point system per injector inlet

Endpoints in a multi-point system per injector inlet

|

Press and HOLD |

Release at 1 second |

Release at 3 seconds |

Release at 7 seconds |

|||

|

Function LED |

Status check |

New canister/reset volume |

manual data point created Useful for installation |

|||

|

search |

connect |

sync. |

||||

|

|

|

Both |

Both Time-stamped data will soon be visible in the GreaseBoss Cloud. |

|

|

|

|

|

|

Contact support@greaseboss.com.au |

(sync fail) |

|||

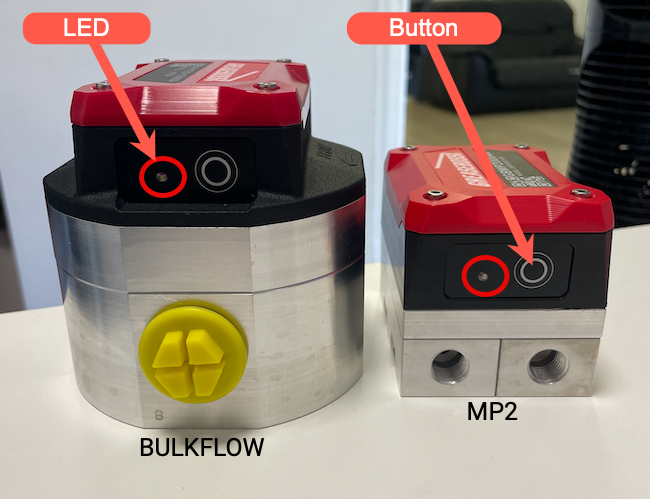

MP2, BULK FLOW, HIGH FLOW & LOW FLOW ENDPOINTS

|

Press and HOLD |

Release at 1 second |

Release at 5 seconds |

Release at 7 seconds |

|---|---|---|---|

|

Function LED |

Status check or power on from deep sleep* |

initiate sync process |

reset pressure calibration MP2 endpoint only. |

|

🟢 LED 🔵 🔴 |

🟢 LED blinks once if OK |

🔵

🔴

🟢

Time-stamped data will soon be visible in the GreaseBoss Cloud. |

🔴🟢🔵

|

|

*devices shipped in deep sleep mode to preserve battery |

|||